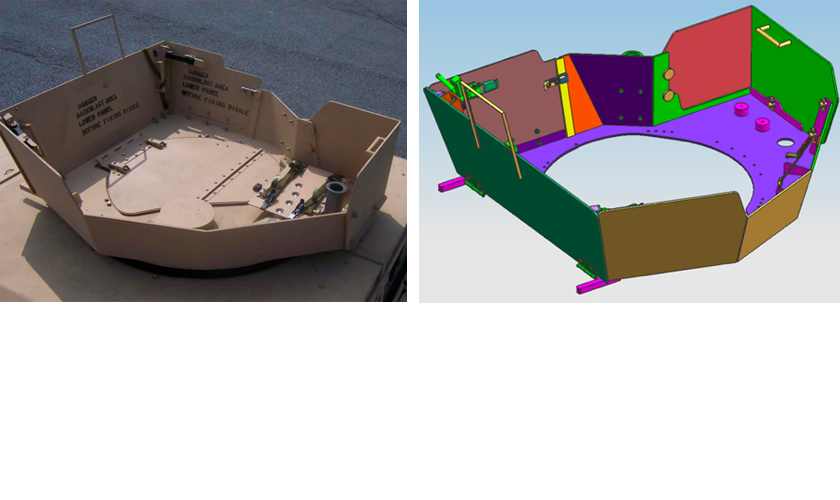

Engineering/Reverse Engineering

With years of experience, American Fabricated Products team of qualified technicians are skilled in determining how metal parts, products or equipment has been manufactured and which materials have been used. We are then able to help businesses enhance product effectiveness and improve production processes.

Design Software:

Solidworks

AutoCAD

Bysoft

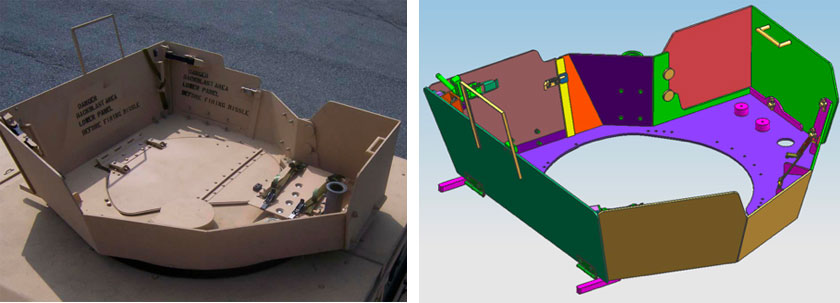

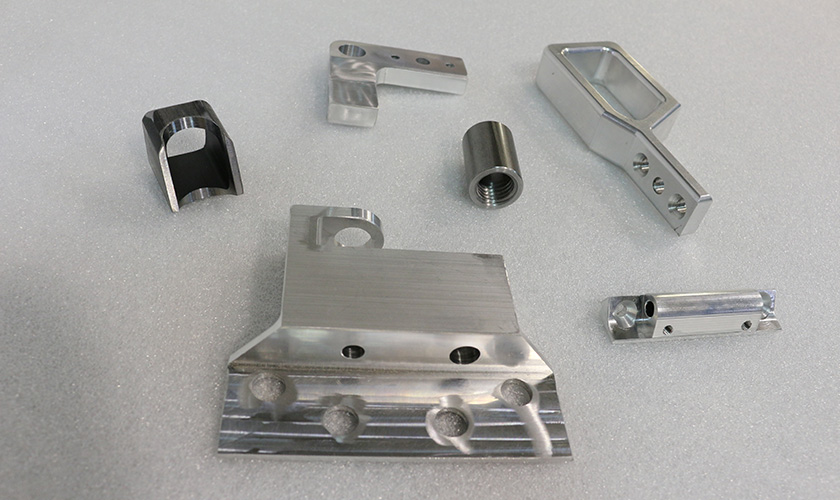

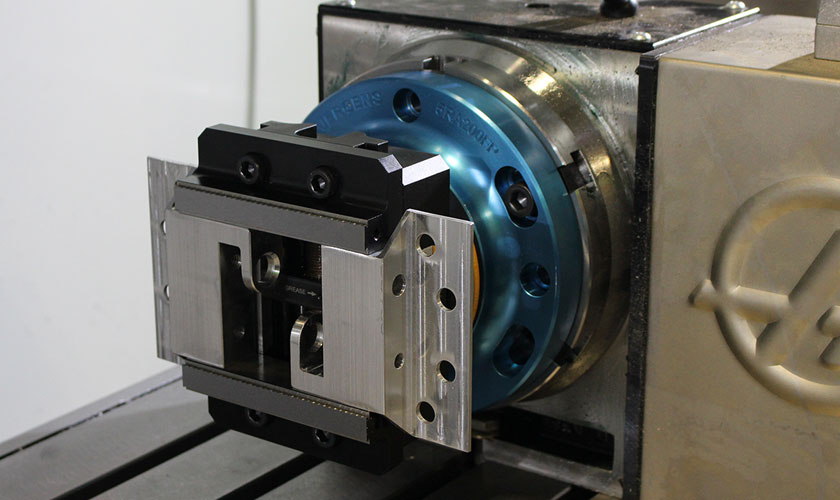

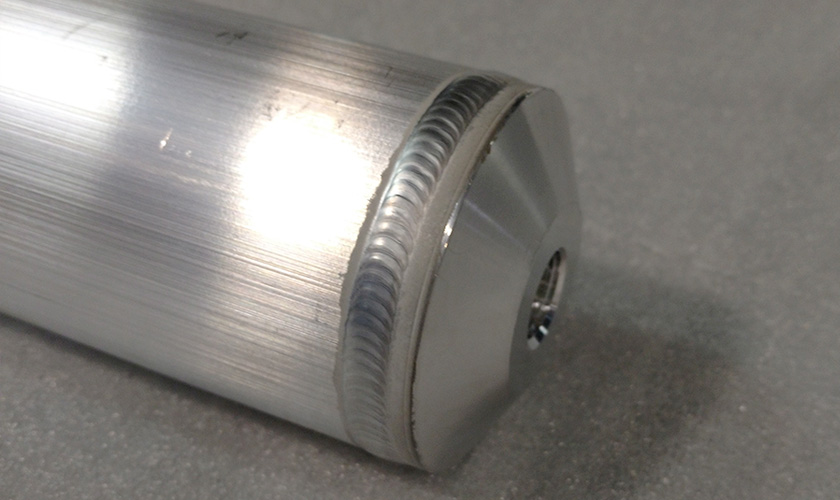

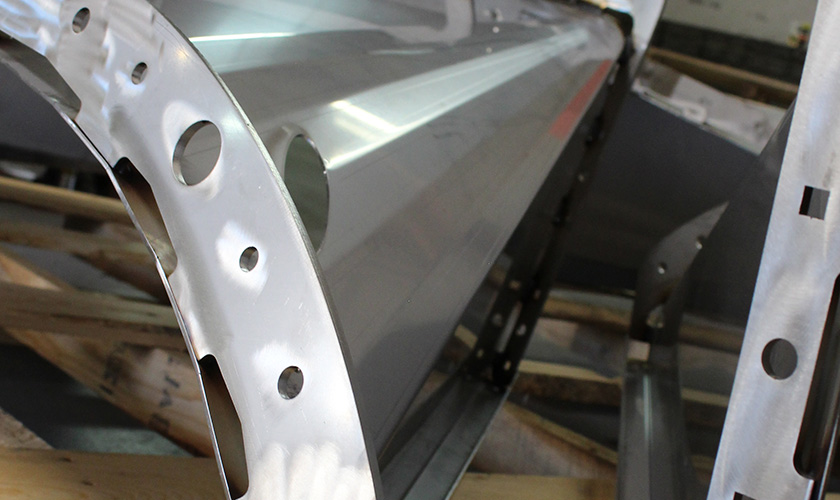

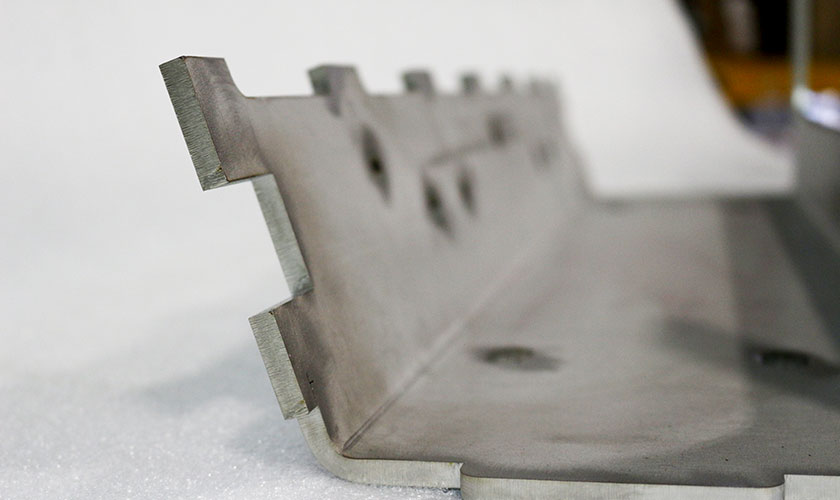

CNC Machining

CNC Machining delivers machined parts quickly and cost-effectively. It is a process in which pre-programmed software dictates the movement of industrials tools and machinery. CNC machining provides the ability for three-dimensional cutting tasks to be accomplished in a single set of prompts.

Haas VF11/50 Vert. Machine Center

30hp Vector drive

(2) Haas VF4SS Super Speed Vert. Machine Center

3 Axis/4 Axis Rotary, 40-Taper, 12,000 RPM

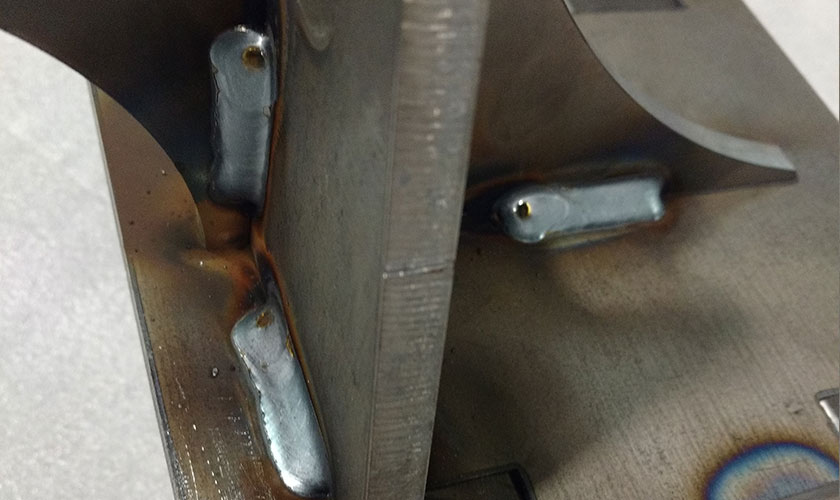

MIG/TIG Manual Weld

American Fab offers Mig and Tig Manual Welding. A MIG welder is a continuous feed of spooled welding wire that burns, melts and fuses both the base and parent metals. We have the ability to weld a variety of materials: steel, stainless steel, and aluminum. TIG welding is a more delicate welding technique which uses long welding rods and slowly feeds them into the weld puddle.

MIG

(3) Miller 350P Alum/Pulse

(2) MillerMatic 252

Lincoln Power MIG

Miller XMT 450 Pulse

TIG

Miller Syncrowave 180SP

Miller Dimension NT450

Lincoln 275 Precision TIG

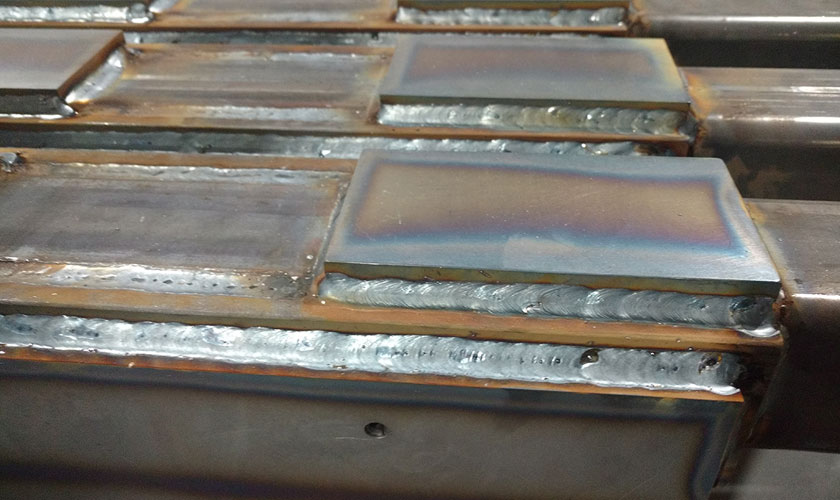

Robotic Welding

Robotic welding is often used for resistance spot welding in high production applications to improve welding speeds, quality, and efficiency. Our team will work with you to analyze your manufacturing project and/or processes to recommend the optimal solution. We are able to meet virtually any metal fabrication needs.

ABB w/ Fronius TPS 400i

ABB w/ AutoInvision450

Laser

We offer laser cutting as a cost-effective solution in producing short run metal parts, due to reduced tooling costs. From prototype to production, American Fab is able to meet, or exceed, nearly all metal fabrication requirements. We utilize the Bystronic BySpeed 3015 and Bystronic ByStar 3015 to ensure that our laser cutting processes are 100% accurate.

Bystronic Byspeed 3015 with 60” x 120” Table

Bystronic Bystar 3015 with 60” x 120” Table w/ Rot. tube cutting

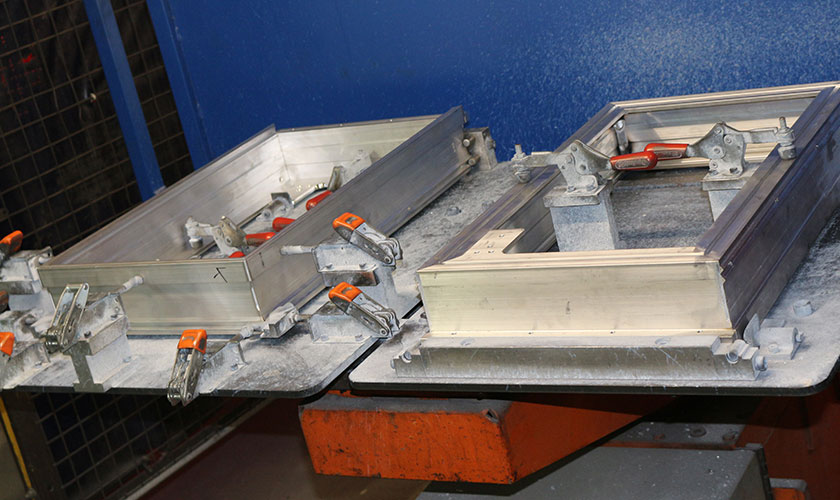

Press Brake

We offer press brake forming services for a wide range of sheet metal fabrications. With extensive tooling capabilities, we are able to form parts into standard or complex shapes. Our press brake machines offer efficiency and precision.

Bystronic175 Ton –10 ft Bed

Bystronic160 Ton –10 ft Bed

Accupress 100 Ton –8 ft Bed

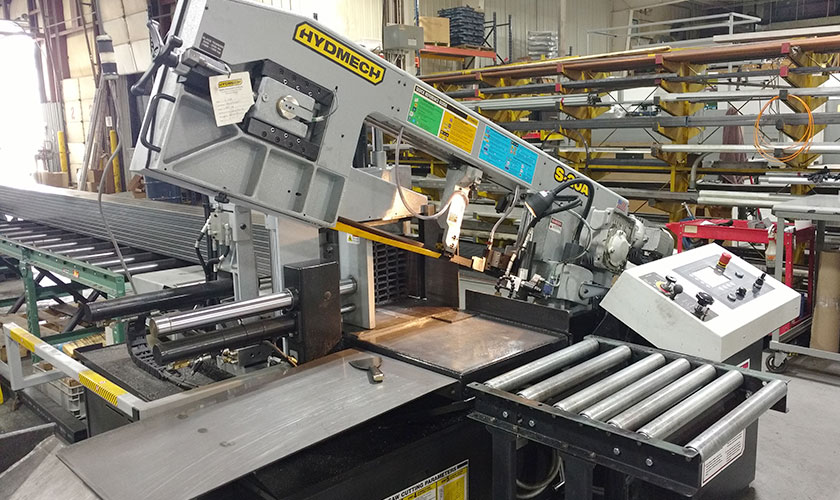

Other Capabilities

Hyd-Mech S20A Horizontal Pivot Band Saw